SCR-PM2 Screw compressors

Basic description

- oil lubricated airend

- one-stage compressors

- speed control by frequency converter

- direct drive 1:1

- electric motor IE4 with permanent magnets

- SOP-20 electronic controller

- pressure vessel with 128 l volume

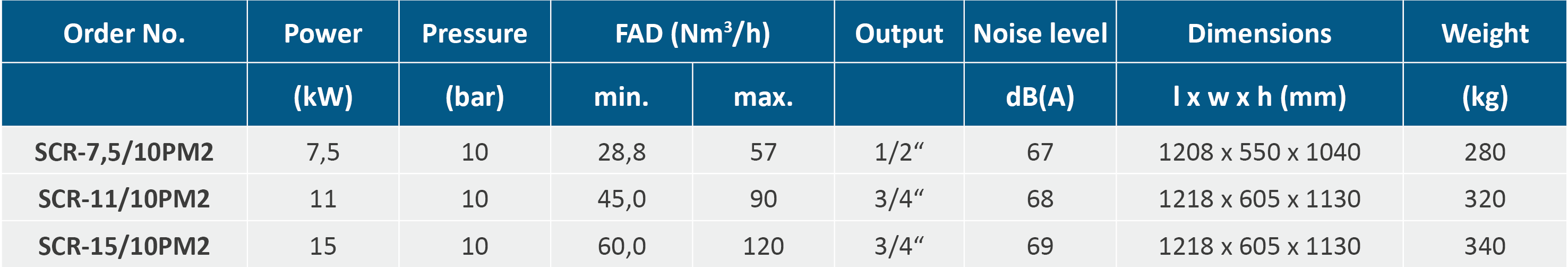

Pressure: 10 bar

FAD: 28,8-120 Nm3/h

Product video

SCR-PM2 video

Get to know SCR-PM2 series through a video presentation.

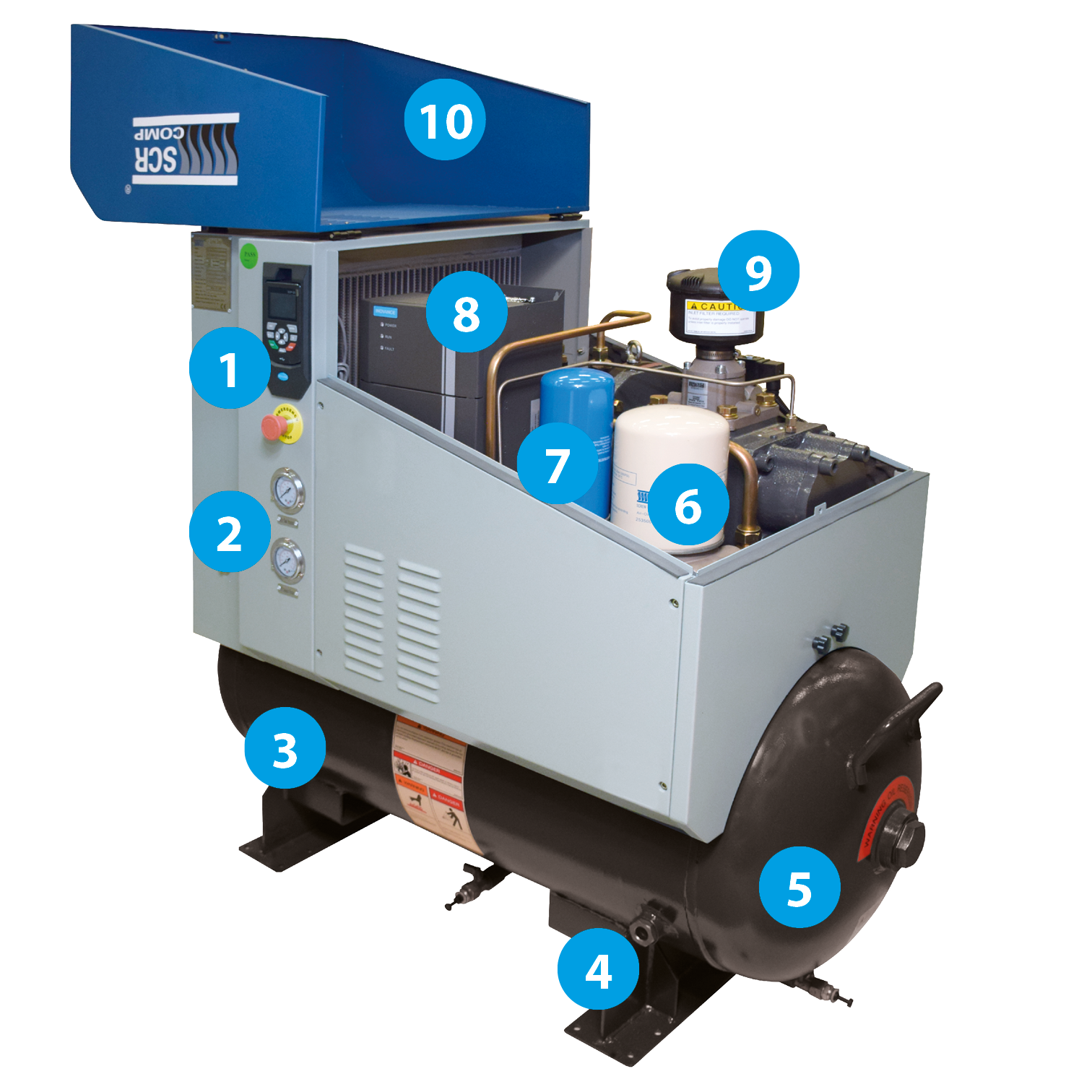

Design arrangement

![]() Electronic controller

Electronic controller

![]() Manometers

Manometers

![]() Air receiver

Air receiver

![]() Oil gauge

Oil gauge

![]() Oil receiver part

Oil receiver part

![]() Separation filter

Separation filter

![]() Oil filter

Oil filter

![]() Frequency converter

Frequency converter

![]() Input air filter

Input air filter

![]() Machine cover

Machine cover

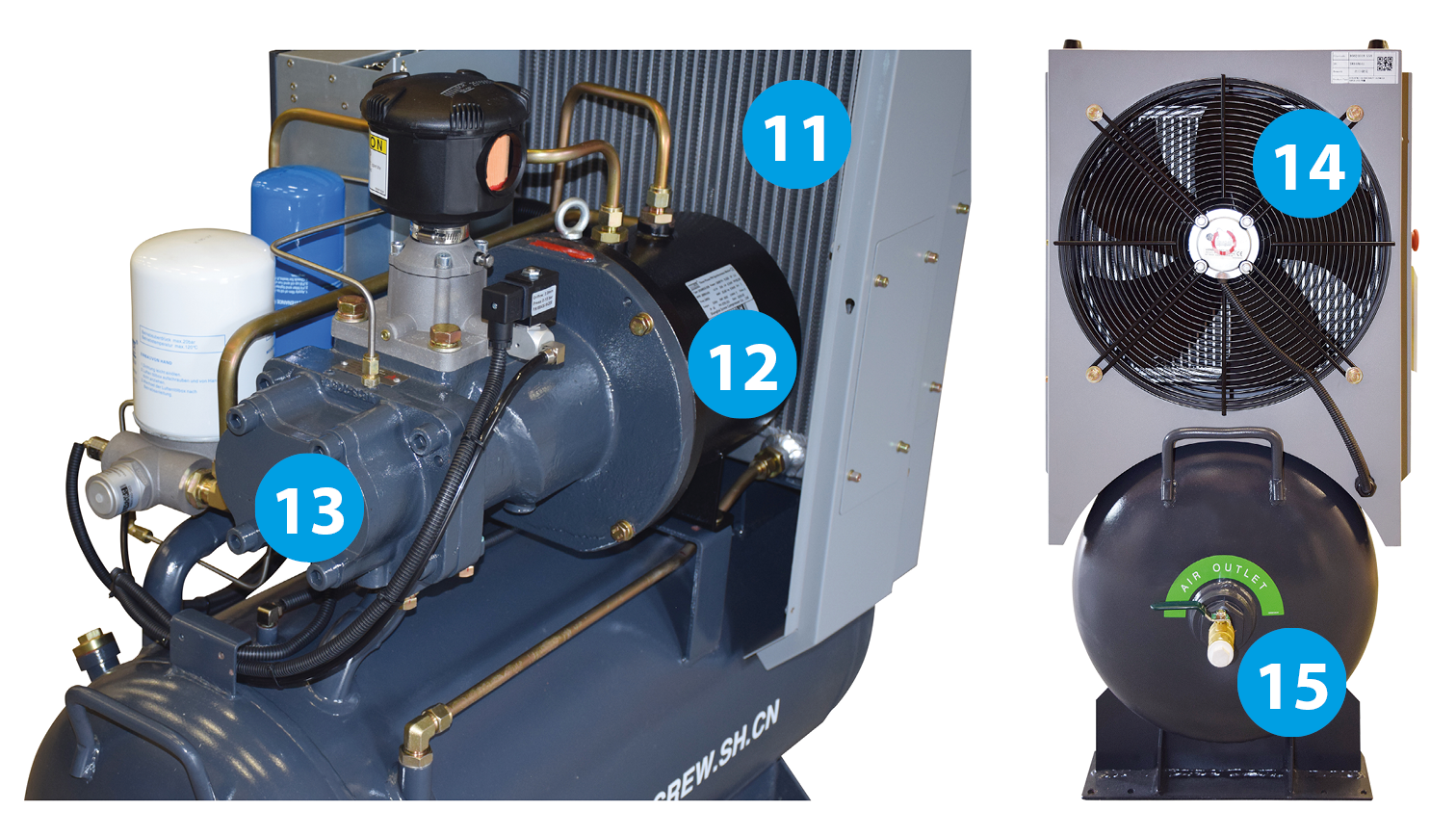

![]() Oil cooler

Oil cooler

![]() PM-motor IE4

PM-motor IE4

![]() Airend

Airend

![]() Fan

Fan

![]() Output ball valve

Output ball valve

Technical properties

Airend

The SCR-PM2 series compressors are equipped with highly efficient ALLY WIN airends, which were designed in Germany and have several international patents.

ALLY WIN airends are equipped with top bearings and ensure long life and high air compression efficiency.

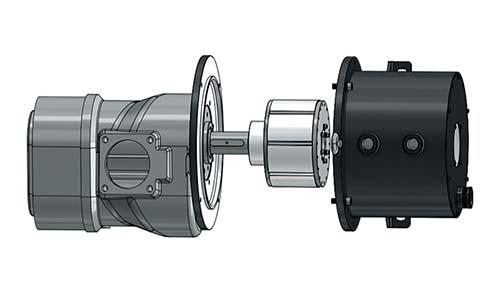

Direct drive

Thanks to the direct connection of the screw block to the electric motor, the SCR-PM2 series compressors operate without any energy loss in the transmission system.

Compared to compressors with V-belts, coupling or gearbox, this eliminates any maintenance and, in addition to energy savings, the user also saves on machine maintenance.

MORE ABOUT DIRECT DRIVEPM motor with IE4 efficiency

The SCR-PM2 series brings the latest in oil-lubricated permanent magnet motor technology to the world of small screw compressors. The used PM motors, due to their design, have an extreme efficiency that exceeds the IE4 efficiency requirements of IEC EN 60034 and exceeds the conventional IE2 efficiency motors used as a standard solution for variable speed compressors by an average of 5%.

In addition, the design of the PM motor does not contain any bearings, which eliminates the aspect of motor maintenance.

MORE ABOUT PM MOTOR

Speed control by frequency converter

Frequency converters are allow to maintain the required output pressure and adapt the speed of the drive unit to the immediate needs of the compressed air supply. Thanks to this modern compressor control system, idling is significantly eliminated and energy savings of tens of percent are achieved.

MORE ABOUT FREQUENCY CONVERTERModern electronic controller

The SCR-PM2 series compressors are controlled by the modern iPanel SOP-20 electronic controller with simple push-button operation, monochrome line display and many useful functions for machine operators and service organizations.

- precise adjustment of the output pressure

- current machine status values

- setting of operating parameters

- weekly plan for cost reduction

- alarms and service alerts

- history of errors

- automatic restart after power failure

- user-friendly operation

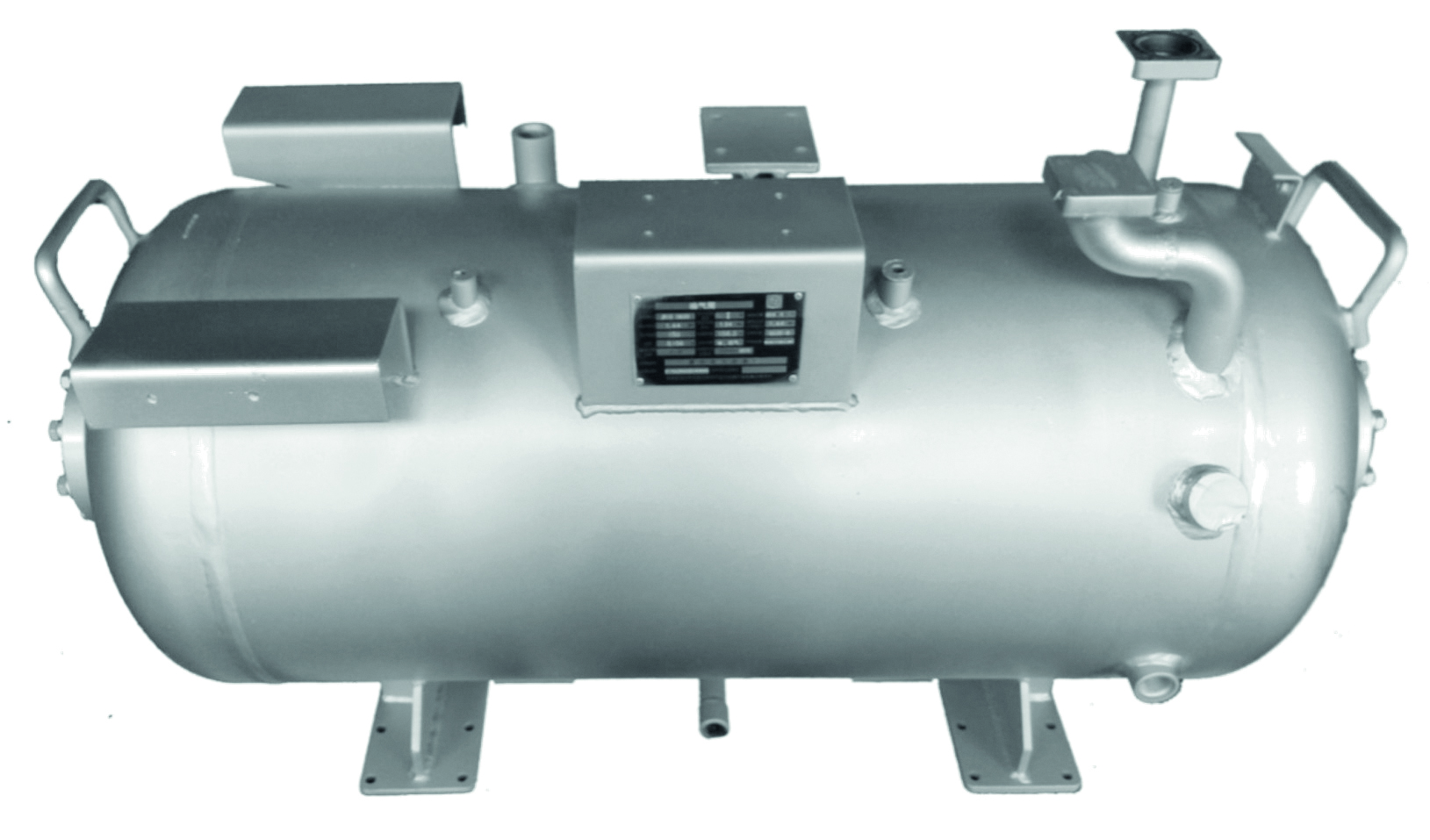

Unique pressure vessel

The innovative concept of the double chamber pressure vessel integrates a receiver for the accumulation of produced compressed air together with a unique oil separation system in the oil section equipped with a labyrinth structure for effective reduction of the oil content in the outlet air. The combination of the two vessels into one unit allows, in particular, a radical reduction in the size of the machine and increases its compactness during installation.

Pipes instead of hoses

On the SCR-PM2 compressors, you will only find metal pipes instead of traditional flexible hoses. This saves you on future hose replacements and eliminates the risk of hose rupture and subsequent air or oil leakage as much as possible.

Minimum dimensions

The SCR-PM2 series is a revolutionary concept in terms of machine dimensions. The SCR-PM2 compressors are so small that they can fit almost anywhere and take up an incredibly small installation area of up to 0.75 m2.

Incredible maintenance comfort

With the SCR-PM2 compressor series you only need to unscrew a single screw and by removing the cover you have immediate access to all the parts. Thanks to the hinged cover, compressor downtime for routine inspections and periodic maintenance is minimised.

Information materials

Presentation

CZ VERSION, PDF 2,59 MBTechnical data

FAD performance is measured in accordance with the current version of ISO 1217, Annex C and is given at an outlet pressure of 10 bar.

The noise level is indicated at a distance of 1 m from the machine.